Higher Tonnage Moulding Parts for Home Appliances

- home

- Higher Tonnage Moulding Parts for Home Appliances

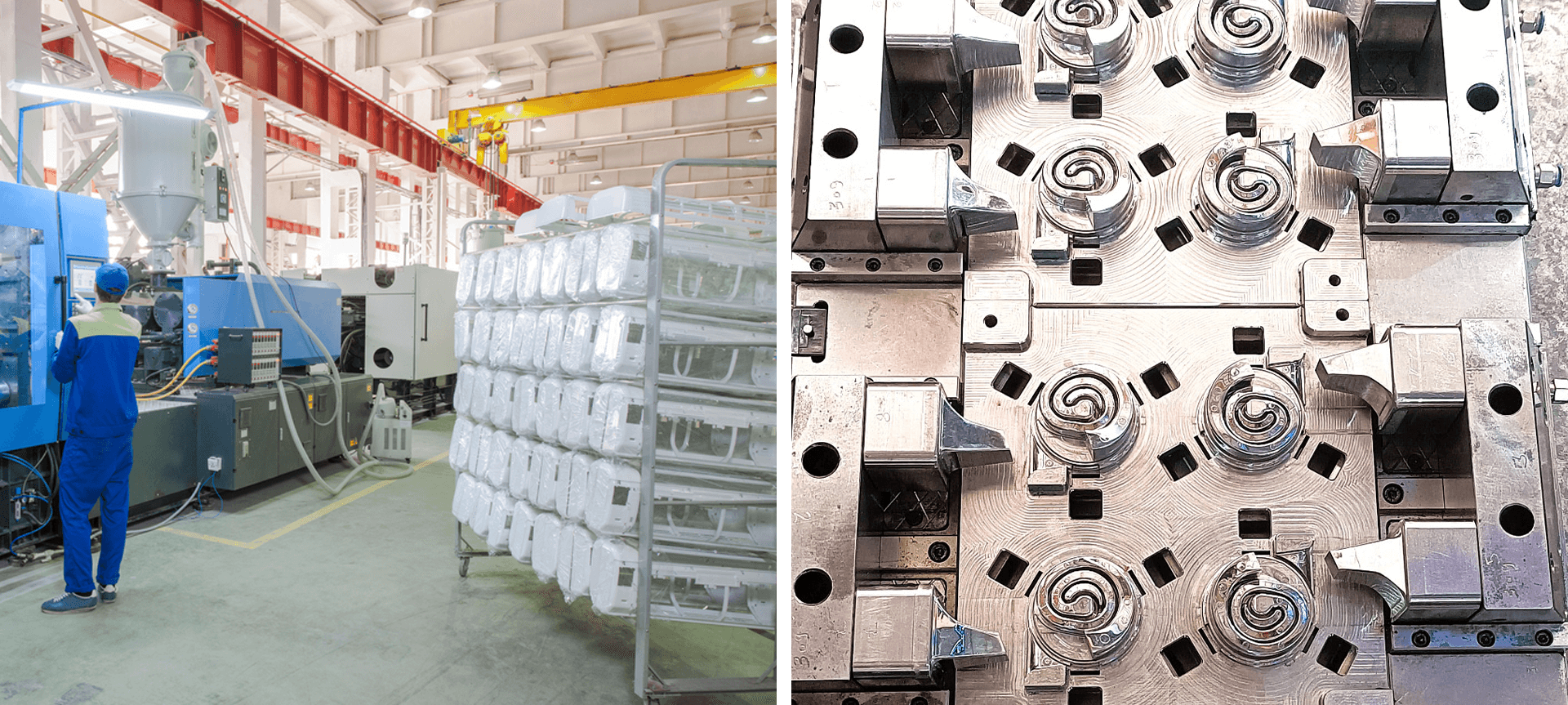

KS Precision Components is one of the leading manufacturers and suppliers of higher tonnage moulding parts for home appliances, such as refrigerators, washing machines, cooler panels and more. We specialize in designing and supplying a range of parts, including washing outer tubes and top covers, refrigerator inner liners and doors, microwave oven housings, AC body panels, and large TV back covers. When you opt for higher tonnage moulding parts for home appliances at KS Precision, you’re investing upfront in better performance, fewer defects, and longer product life cycles.

Our heavy-duty moulded components elevate product durability, minimize failure risks, and enhance manufacturing efficiencies and end-user satisfaction. We are committed to innovation, customer satisfaction, and technology upgradation. We use only top-grade raw materials and advanced technologies in the manufacturing process. So, our products are of top quality that meet international standards.

What Is Higher Tonnage?

Tonnage is the clamping force in compression moulding or injection moulding technology that is applied to keep mould halves closed during material injection and curing. With our Higher Tonnage Moulding Parts for Home Appliances:

- Bigger and more complex moulds can be handled without bending or leaving ugly marks.

- Tougher, thicker plastics (used in heavy-duty appliances) can be filled perfectly, without gaps or weak spots.

Salient Features of Our Higher Tonnage Moulding Parts :-

- Supports larger and bulkier mould sizes.

- Suitable for parts with thicker sections.

- Provides a stronger clamping force for secure moulding.

- Handles complex and detailed designs with ease.

- Works well with high-viscosity and reinforced plastics.

- Produces durable and long-lasting components.

- Prevents warping, sink marks, and surface defects.

- Ensures high-dimensional accuracy and precision.

- Ideal for heavy-duty and load-bearing applications.

- Maintains consistent quality across large production runs.

- Minimizes defects, rejects, and costly rework.

- Allows faster cycle times and better productivity.

- Compatible with multi-cavity moulds for efficiency.

- Versatile enough for home appliances, automotive, and electronics.

Why Choose KS Precision?

At KS Precision, we’ve built our expertise around precision moulding under high tonnage regimes. Our engineers make these moulding presses for high clamping forces and correct alignment. They are heat-resistant, UV stable, and have impact strength. The team conducts a thorough examination and ensures rigorous quality control. They inspect the surface, check dimensions, and test the stress. Get in touch if you are looking for a reliable and popular manufacturer and supplier of Higher Tonnage Moulding Parts for Home Appliances.